Towing Wire Rope

Wire rope plays an important role in deep-sea towing. As operating conditions and vessel size can vary widely, it is critical to select a suitable wire rope to warrant a safe and efficient passage.

For wire rope maintenance, we use lubricants.

Recommended Wire Rope Constructions

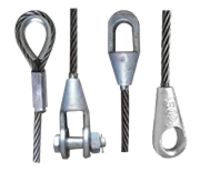

End Terminations

Towing wire rope requires an end termination that can safely and easily attach the towed vessel to the tugboat. Typically, this is a thimble eye or a socket.

Fittings

Socket

Usually open and closed spelter sockets and Anchor Pendant sockets (Pee-Wee sockets) are used. All our sockets are poured with Wirelock, the original cold socketing resin and the first socketing system to meet the performance criteria of DNV for offshore wire mooring rope, currently the DNV-OS-E304 standards.

Our sockets are made of high quality cast steel supplied in hot dipped galvanized finish and comply with EN10204 3.1/3.2, JIS F3432 or RR-S-550D, Type B standard.

We are the authorized distributor for SILVERLINE (Germany) sockets.

Thimble

Sometimes thimbles are used for reinforcement at the eye. Our thimbles are manufactured according to the BS 464, JIS B2802 (Type A) or FF-T-276b Type III (G414) standard. The expertise and the Talurit splicing system in place at TEHO produce safe and reliable thimble terminations.

newsletter

Please subscribe to our newsletter